Maryport Steamships including The Flying Buzzard

History

The Flying Buzzard was built in 1951 by Ferguson Brothers of Port Glasgow for the Clyde Shipping Co. of Greenock. The prefix ‘Flying’ was used on a succession of tugs belonging to Clyde Shipping, dating from 1856 when the Flying Childes was built at Shields, apparently named after a famous racehorse. In 1951 there were a further nine boats with ‘ Flying’ in their name belonging to the company, and two earlier ships had been named Flying Buzzard, built in 1895 and 1900 respectively. Two other tugs were built in 1951 as sister ships to the Buzzard, the Flying Merlin and the Flying Petrel. The latter worked regularly at Workington. These three were the last steamships to be built for the Clyde Shipping Co. by Ferguson Brothers.

The Flying Buzzard was launched on 21st May 1951 in Port Glasgow Outer Harbour and, after sea trials, she proceeded down river to start her career with the Clyde Shipping Co. Flying Buzzard was employed by the company mainly as a tug, but she had a secondary purpose as a tender to the passenger liners which, at that time, travelled up the Clyde. The passengers would disembark onto the Buzzard and be taken safely up the Clyde to Glasgow. Her passenger certificate shows her to have been allowed up to 150 passengers. First class clients would have travelled in the passenger saloon on the upper deck, abaft the bridge, with the rest of the passengers being spread about the two open decks, which offered little shelter from the Clyde winds.

The Flying Buzzard had been in operation for less than a year when, in April 1952, disaster struck. The Buzzard, together with her sister ship the Flying Petrel, were towing the 9,819 ton tanker Esso Appalachee from the discharge berth at Bowling to the Tail-of-theBank, when the tanker fouled her tow, sheered and struck the Flying Buzzard amidships. The tug started to go down by the stem, her engine room [flooded, and there was immediate danger of her sinking mid-channel and blocking the busy shipping lanes of the Clyde. Her Commander, Captain Cameron, steered for a sandbank opposite Dumbarton, where she sat, submerged in 26 feet of water. Luckily the crew managed to disembark without mishap.

Despite the damage to the Buzzard, it was considered that there was a good chance of her being salvaged. Therefore Metal Industries (Salvage) Ltd . was contracted to attempt the task on a “no care, no pay” basis. The ship’s main engines and deck auxiliaries, such as pumps and the generator, were removed to Ferguson Brothers for repair. She was refloated on 23rd May and taken to Laments Repair Yard in Port Glasgow.

By 6th October she was back in commission and returned to work on the Clyde, where she remained for the next eleven years, serving as a tug and tender. In 1963 she was sold to the Dundee Harbour Trust and her name was changed to Harecraig II. After a long career, the tug was sold in 1983 for non-payment of harbour fees to the Maryport Steamship Co. Three years later she was purchased by Allerdale District Council, with the VlC 96, as the basis of a steamship museum in the Elizabeth Dock at Maryport.

Captain Daniel Cameron and the Crew of the Flying Buzzard

The original crew of the Flying Buzzard comprised a Master (Captain Daniel Cameron), Mate (James Kelly) , Chief Engineer (Robert Robinson) , Second Mate (Jackie Chalmers) , two Deckhands (Con Gill & Murdo McLeod) and two Firemen (Con McGeecham & Tommy Kilday).

The full complement of the Buzzard would have been four officers and ten crew. There is adequate accommodation on board for all of the crew, although they usually stayed on board for one or two nights at the most, as the boat operated mostly within the River Clyde.

Captain Daniel Cameron was born in Greenock in 1890. At the age of eighteen he began his long maritime career, and his association with the Clyde Shipping Company, working as a deckhand on the steam paddle tug Flying Sprite. At the outbreak of World War One he volunteered for sea rescue work. In 1917, whilst serving on H.M. Tug Flying Falcon, he was shipwrecked off the island of Islay during a fierce storm. In the latter part of the war Daniel Cameron served as First Mate on the rescue ships H.M.5. Zaree and H.M.5. Sonia and took part in several exciting rescues from their base on the Scilly Isles.

After the war Dan Cameron returned to his native Clyde and in 1933 became Captain of the Flying Spray. On Saturday, 2nd April 1938, a windy and choppy day, the Flying Spray, together with the tug Swallow, was taking the Federal liner Cumberland down the River Clyde on the first stage of her voyage to New Zealand. Owing to the strong winds the liner dropped her anchor to prevent a collision with another ship. When her propellers thrashed in reverse the Flying Spray was quickly sucked in, a gash was torn in her midships, sending her to the bottom in a matter of minutes. The seven members of the crew, using rope ladders were saved by the offending liner Captain Cameron, the last to leave the doomed vessel, prepared himself to jump into the cold waters of the Clyde and to swim ashore. Fortunately a small motor launch raced to his assistance shortly before the tug disappeared. Dan Cameron served on the Flying Spray until being given command of the newly built Flying Buzzard in 1951. He retired on 20th September 1959 but, sadly, died only seven months later, on 18th March 1960, aged 70 years. In all he had been at sea for 52 years.

Specifications

The Flying Buzzard is a single screw propulsion steam tug of steel, riveted construction. Her tonnage is 261 and her dimensions are: length 106ft, beam 27ft, draught 13ft.

The fuel oil on which the Buzzard runs must be heated before it is burnt. Therefore the fuel bunkers, which hold up to 84 tons of oil, have a network of heating elements running through them .

The main engine is a two cylinder compound reversing steam engine with a 1200 brake horsepower rating and a working steam pressure of 130 pounds per square inch

The boiler is double fronted, which allows the air to be warmed before it enters the combustion chamber and helps keep the front plate of the boiler cool. Nevertheless, it would still have been far too hot to touch.

On the main deck of the vessel, attached to the reinforced bulkhead abaft the Galley, is the Ferguson Newark patent spring tow hook, to which were attached the cables for towing ships. This was regularly tested to a static load of 30 tons.

The Flying Buzzard also has on board a steam driven generator that provided power for the lights, the ship to shore radio, and the pumps.

When her propellers thrashed in reverse the Flying Spray was quickly sucked in, a gash was torn in her midships, sending her to the bottom in a matter of minutes.

The Story of the VICs

VlC stands for Victualling Inshore Craft. These small vessels were built during World War Two to supply naval vessels and bases around the country. Their cargoes included general stores, ammunition, torpedoes, water and fuel.

The design of the VlCs was derived from that of the Clyde “puffers”. These small vessels traded in and around the Highlands and Western Isles of Scotland from the late nineteenth century. Their fiat bottoms enabled them to go into shallow ports and go aground at low water to discharge their varied cargo. The “puffers” earned their nickname from the their engines, which originally did not have condensers, so the exhaust steam went straight up the funnel, like a traction engine. These sturdy boats have been immortalised in Munro’s Tales of Para Handy.

During World War One the puffers supplied the warships and larger supply vessels at Scapa Flow and were sometimes the only link with the Western Isles. The qualities shown by these stalwart craft may have influenced the decision to order the building of the VlCs in the next war.

The first series of VlCs were based on the design of two puffers, Anzac and Lascar, launched in 1939. They were 66 ft (20 metres) long and 63 of this type were built. Fifty-four were steam powered and nine diesel, which is surprising as diesel had become the standard fuel for vessels of this size. Possibly the war effort had already stretched the diesel engine builders, leaving steam engine suppliers with spare capacity. Also coal was home produced while oil was imported.

The second series of VlCs were 80 ft long (24 metres) and has a cargo capacity of 120 tons. Of the 35 which were built, 33 still had steam propulsion. They were equipped with a more efficient Cochrane boiler and Crab tree engine, the controls for which were no longer in the wheelhouse, but in the Engine Room. The accommodation was more generous, with berths for six crew and included the luxury of a galley. The lines of the vessel changed from the earlier sheer, rounded hull to emulate the rectangular form and hard chines of other wartime designs.

During World War Two the VlCs worked in ports all over this country, while some were shipped abroad, carried by larger vessels. For example VIC 2 was taken to Malta, and the nine diesel engined first series VlCs were used in the Far East as small tankers.

VlCs also continued the tradition of the World War One puffers, being used a naval bases in Scotland such as Scapa Flow, Rosyth and the Clyde. They caried all sorts of cargo including aviation spirit, cement and general stores, such as the corned beef VlC 77 is recorded as supplying the fleet.

After the war several VICs were sold to companies that carried on the traditional puffer trade in west Scotland, such as the VlC 7 and VlC 11. A former crew member describes the typical work of a VlC on these routes:

The “puffers” earned their nickname from their engines, which originally did not have condensers, so the exhaust steam went straight up the funnel, like a traction engine

“We loaded coal at Troon and sailed to the islands around the coast oJ Scotland, we once sailed to the Isle of Gigha with bricks and cement for the crofters.”

Other VlCs remained in Admiralty Service. Diesel engines replaced steam machinery in several, while others were altered beyond recognition . The VlCs that remained in naval service continued as general supply vessels for the larger ships, initially with Port Victualling Departments and subsequently with the Port Auxiliary Service, which was formed in 1958 combining many different classes of service craft.

Some carried ammunition, being classed Naval Armament Vessels. Others were converted to carry water, such as VlC 65, which supplied distilled water for the boilers of warships under refit. By 1978 only VlC 56 and VlC 65 were left in service at Rosyth. VlC 65 was broken up in 1979 and VlC 56 was purchased in September 1978 and moved to the River Thames.

Several VlCs passed into the hands of overseas owners. VlC 81 went to Eire in the 1970s and in 1980 was recorded taking live fish and crabs to Europe . VlC 10 was sold to a Dutch owner, converted to diesel and renamed Emmanuel In 1950 she moved once again, to Norway.

Of the diesel VlCs shipped to the Far East, VlCs 40 and 45 appeared later in Hong Kong, VlC 47 at Trincomalee and VlC 48 in Singapore. Other VlCs worked from Malta and Sicily into the 1970s.

VIC 96

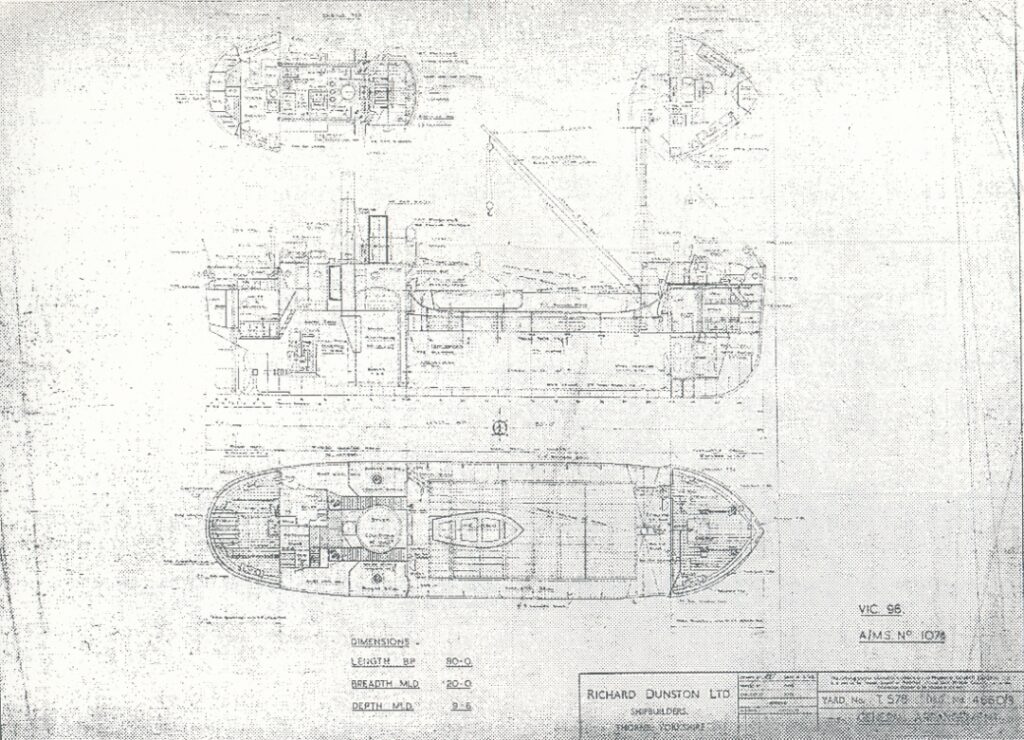

VlC 96 was built in 1945 by Richard Dunstan Ltd. at Thome, near Doncaster. She is one of the second series of 80 ft VlCs and is steam powered, retaining her original Crabtree engine. Richard Dunstan Ltd., which built forty of the ninety-eight VlCs, was established in 1858. The major business of the firm at that time was rope manufacture, but they also built barges and small wooden craft. They ceased making rope in 1911 and from 1922 specialised in steel vessels of up to 140 ft (42.7 metres).

In 1931 the firm took over Henry Scarr of Hessle on the River Humber, which enabled Dunstan’s to build larger vessels. In 1960 most of the design and estimating staff were transferred to Hessle and in the mid 1980s the Thome yard was closed.

The VlC 96 was based at Sheerness in Kent, being employed on general store carrying duties. She often sailed between Sheerness and Harwich. On 11th April 1949 she was renamed C668. In 1956 she underwent a refit in Lowestoft, after which the Victualling Department considered disposing of her. C668 survived as a naval vessel, however, remaining at Sheerness until the naval dockyard closed in 1959. The ship was transferred to Chatham, where a survey estimated her future hull life at 20 years. In 1960 she was involved in a collision with the SS Durango, the damage being repaired by Harland &: Wolff, London. Finally in 1972 the boat was referred for disposal, and was towed away from Chatham by her new owner on 10th August 1972.

VlC 96 had been bought by Mr RW Fielding of Dublin, who had also owned VlC 1 in the 1960s. She was kept in various London docks, but maintained in good condition, both mechanically and structurally, although she did suffer from vandalism.

In 1981 the vessel was purchased to become part of an array of steam vessels in Maryport Docks. She was steamed all the way from London’s Limehouse basin to Newcastle. This was a remarkable journey for a ship of her age, although, unfortunately, she did run our of coal on the way and had to put into Bridlington for a fresh supply. From Newcastle the VIC 96 proceeded up to Scotland, through the Caledonian Canal, then down to Maryport.

Five years later, in 1986, the VlC 96 was purchased by Allerdale District Council, with the Flying Buzzard. The VIC was not in such good condition as the Buzzard and there began a period of restoration which was to last several years.

The Restoration of the VIC 96 described by the Engineer Joe Cochrane

‘At first viewing the VIC 96 was a horrifying sight. There was no wheelhouse. The top of the funnel was corroded so badly that it was holding on by approximately threequarters of its circumference. At most there were ten or twelve hatch boards remaining and the canvas hatch cover was in shreds. A rather dilapidated companionway, with a broken bottom step and no handrail, led from the starboard aft hatch coaming down into the hold. The hold itself was full of rubbish, including a cast steel skip partly full of stone ballast. When the skip was raised we found that it had been placed in that position to secure a wooden plug being used as a stopper where penetration of the hull plating had occurred, just inboard of the tum of the bilge. We replaced the skip very quickly!.

At a convenient time, arranged with the Harbour Master, the dock was allowed to empty. With the VIC 96 sitting on the bottom of the dock and the plugged section clear of the water, the skip was removed and the area surrounding the plug thoroughly cleaned. A box to the depth of the frame on each side of the plug was formed, enclosing the plug. The box was then filled with concrete. When this was done the hold was completely cleared out. The next stage was to replace the timber ceiling, which was almost totally rotten and unsafe to walk on. This was achieved using timber recycled from an old mill being demolished near Egremont.

At the same time it was decided to increase the ship’s draught in order to reduce the effect of wind and sea swell entering the dock when the dock gates were open. This made the VIC 96 more comfortable for visitors. The method used to increase her draught was to fill the space below the ceiling with permanent ballast in the form of concrete, the depth and spread of which had to be calculated precisely. As it was planned to present the ship as a museum, we felt that there should be access from the hold into the engine room so that the machinery could be included as an important part of the tour. To achieve this the starboard coal bunker was converted into a passageway linking the two spaces.

Thought needed to be given to the positioning of a companionway leading from the hatch [Op [0 the bottom of the hold. Its site had to take into account easy access for visitors, as well as the trim of the vessel. We did this by siting the companionway more or less amidships, so that the addition of the weight of the companionway would help lower the ship in the water and not affect the trim. The companionway was prefabricated in the workshops of the AlIerdale Employment Training, who also assisted with the basic setting up and installation.

Finally the interior of the hold was treated to prevent corrosion and against condensation. All the old paint had to be removed from the ship’s sides, the fore and aft bulkheads, the hatch coamings and hatch beams. This was done using a small air compressor, a pneumatic chipping gun and a lot of chipping hammers.

During the severe gales in January 1987, the funnel was blown from its precarious position and deposited on the starboard quarter of the poop deck. Fortunately a chance telephone call to Eric Holmes, Manager of the Sellafield Apprentices Training Centre resulted in an offer to rebuild the funnel if the old one could be transported to Sellafield to be used as a pattern.

Running concurrently with the earlier stages of restoration, a new wheelhouse was in the process of being built. At first, we had no idea how to start rebuilding it. We had no drawings or information of any kind, only a space on the deck where it had been. A telephone call from a shipbreaker in Millom saved the day. He told us that he was taking delivery of the VIC 52 and that I was welcome to go and take a look at her to see if there was anything that might be of use to us. On arrival I found the wheelhouse all intact, complete with compass and compass stand. The proprietor of the yard had the whole thing removed in one piece by cutting it off below the steel deck supporting it. He then loaded it whole onto a wagon and delivered in to the dockside in Maryport.

After dismantling, re-usable timbers were salvaged and removed to a carpenters shop in the town for use by the unemployed and managed by the Manpower Services Commission. Although all dimensions had been taken before dismantling, there were discrepancies . These could, however, be accounted for by the fact that, while both the VlC 96 and VIC 52 were superficially identical, they had been built by different shipbuilders. This meant that there had to be constant checking and supervision during the reconstruction. Nevertheless at the end of the day we had a brand new wheelhouse for our vessel , that was well constructed and looked good.”

When the skip was raised we found that it had been placed in that position to secure a wooden plug being used as a stopper where penetration of the hull plating had occurred …

The Hold

The Hold is designed as an interactive gallery for children of all ages The exhibits illustrate the three forms of power used to propel and operate vessels throughout maritime history.

Muscle Power

The crew used to raise and swing the mighty spars and sails that drove a sailing ship. Their muscle power was multiplied through dozens of simple tackles. A tackle is simply a rope rove (led) through one or more blocks (frames) containing sheaves (pulleys) . The more sheaves the rope passes over the greater the purchase (power) gained to lift or pull – but tackles of many sheaves have enormous friction, which means in practise a loss of power.

Wind Power

A sailing ship needs its sails to use energy in the wind and move forward. The model Brigantine in The Hold demonstrates this.

Steam Power

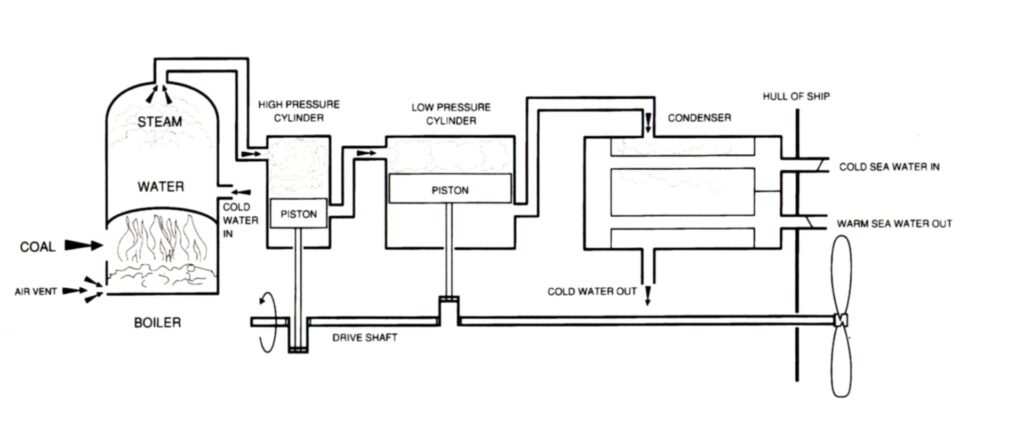

With the advent of steam power, ships no longer had to depend on the wind to move. A steam engine uses a fuel such as coal or oil to provide the energy needed. When the fuel is burned the energy, in the form of heat, is used to boil the water, making steam. The pressure of the steam drives the engine, which turns the propeller and pushes the ship forward .

This is a diagram based on a compound engine, such as the engine of the VIC 96. With this type of engine the steam is made to work on more than one piston, thus enabling these engines to produce rotary motion, rather than simply reciprocating. Steam is generated in the boiler and then goes to the first, small high pressure cylinder. After the steam has pushed the piston down, some power remains, and it is transferred to the second cylinder to work another piston. The steam is now at a lower pressure and so to compensate for this drop, and to retain equal power on each piston, the cylinder and piston have to be larger In some ships triple or quadruple expansion engines, with three or four cylinders were used, each cylinder being larger than the last.

Once the steam has done its work, it enters the condenser where it is cooled by a network of tubes containing sea water. It then returns [0 the boiler as cold water, where it is used again, completing the cycle.

The VIC 96 Engine Room Specifications

Main Engine: Built in 1945 by Crabtree &: Co (1931) Ltd of Great Yarmouth

Type: Compound two cylinder steam reciprocating with separate

condenser

Data: High pressure piston – 10.5 inches diameter with piston valve

Low pressure piston – 22 inches diameter with slide valve

Stroke: 14 inches 180 Brake Horse Power

The engine also runs the following pumps:

Boiler: Water Feed Pump, Air Pump, Condenser Cooling Pump, Bilge Pump

Boiler Built in 1945 by Cochrane &: Co (Annan) Ltd

Type: Vertical, cylindrical, coal fired with horizontal fire -tubes and two furnace openings

Data: Diameter 6′ 6″; Height 14′ 0″

Operating pressure – 120 lbs per square inch

Heating Surface – 450 square feet

Grate Area – 22.5 square feet

Number of tubes – 143

Boiler weight (empty) – 7.25 tons

Water capacity at cold level – 3.65 tons

Maryport Steamships including the Flying Buzzard booklet

Maryport Steamship Flying Buzzard booklet

Click the red text below and the original booklet will download into a new window – it might take a few seconds.